How to Identify Top Injection Molding Services in China

The important meeting has recently finished, your new project has the green light, the timeline is aggressive, and the budget is… well, let’s just say it’s tight.. Then someone—maybe your boss, maybe the finance director—utters the phrase that sends a little jolt down every project manager’s spine: “We should look at sourcing this from China.”

Of course, you acknowledge. On paper, it’s logical. Savings can be substantial. But your mind is already racing. You know the rumors, don’t you? The quality disasters, the communication black holes, the shipment that shows up three months late looking nothing like the sample. It can feel like you’re being asked to walk a tightrope between landing a huge cost win for the company and steering your project straight into a ditch.

Here’s the thing, though. Procuring plastic mold needn’t be a roll of the dice. It’s a project, just like any other. And its outcome hinges on the approach you take. It isn’t about the cheapest offer but about choosing the right supplier and running the process transparently. Forget the horror stories. Here’s a practical playbook to nail it.

Step One: Do Your Homework

Before you mention “supplier” or browse Alibaba, organize your internal data. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. You can’t expect a factory on the other side of the world to read your mind. Sending a vague request is like asking a builder to quote you for “a house.” You’ll get wildly varied quotes that are useless.

Your RFQ should be bulletproof—clear, detailed, and unambiguous. This package is your project’s foundation.

So, what goes in it?

Begin with 3D CAD models. They cannot be skipped. Stick to universal formats like STEP or IGS to avoid any compatibility headaches. This is the authoritative CAD geometry.

Yet 3D models don’t cover everything. You also need detailed 2D drawings. This is where you call out the stuff that a 3D model can’t communicate. Think tolerances, material grades, finish specs, and any feature-critical notes. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

Then specify the material. Don’t just say “Plastic.” Nor just “ABS.” Be explicit. If you need SABIC Cycolac MG38 in black, say exactly that. Why be exact? Because there are thousands of plastic variations. Naming the precise grade locks in the mechanical, thermal, and aesthetic properties you need with what is plastic mold.

They can offer alternatives, but you must provide the initial spec.

Finally, include the business details. What’s your forecasted annual volume (EAU)? They need clarity: is it 1,000 total shots or a million units per annum? Cavity count, tooling cost, and per-unit pricing depend on volume.

Hunting for the Best Supplier

Now that your RFQ is pristine. who will you target? The web is vast but overwhelming. Finding suppliers is simple; finding quality ones is tough.

Your search will likely start on platforms like Alibaba or Made-in-China.com. These are great for casting a wide net and getting a feel for the landscape. Use them to build a shortlist, not the final list. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

However, don’t end your search there. Perhaps hire a local sourcing specialist. Yes, they take a cut. Yet top agents deliver reliable, audited suppliers. They handle local liaison and oversight. For a first-time project, this can be an invaluable safety net. Think of it as insurance for your project timeline.

Also consider trade fairs. If you can attend, shows such as Chinaplas transform sourcing. Nothing beats a face-to-face conversation. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. Also, leverage the tried-and-true referral network. Consult trusted colleagues. Peer endorsements carry huge weight.

Separating Real Suppliers from Pretenders

After firing off that RFQ to a broad pool, the quotes will start trickling in. You’ll see ridiculously low offers and steep quotes. Now, sift through and shortlist 2–3 reliable candidates.

How to proceed? It involves both metrics and gut feel.

Step one: audit communication. Is their turnaround swift and concise? Is their English good enough for complex technical discussions? But the key: do they probe your RFQ? The best firms will question and suggest. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” Consider that a big green light. It proves their expertise and involvement. Anyone who simply agrees to all specs is a red flag.

Afterward, verify their technical arsenal. Ask for a list of their equipment. Seek samples or case studies of comparable projects. Don’t pick a micro-molding shop for large components.

Next up: the factory audit. You can’t skip this. As you vet staff, you must vet suppliers. You can travel or outsource a local inspector. They perform a one-day factory inspection. They authenticate the firm, review ISO credentials, evaluate machines, and survey operations. That small investment can save you thousands.

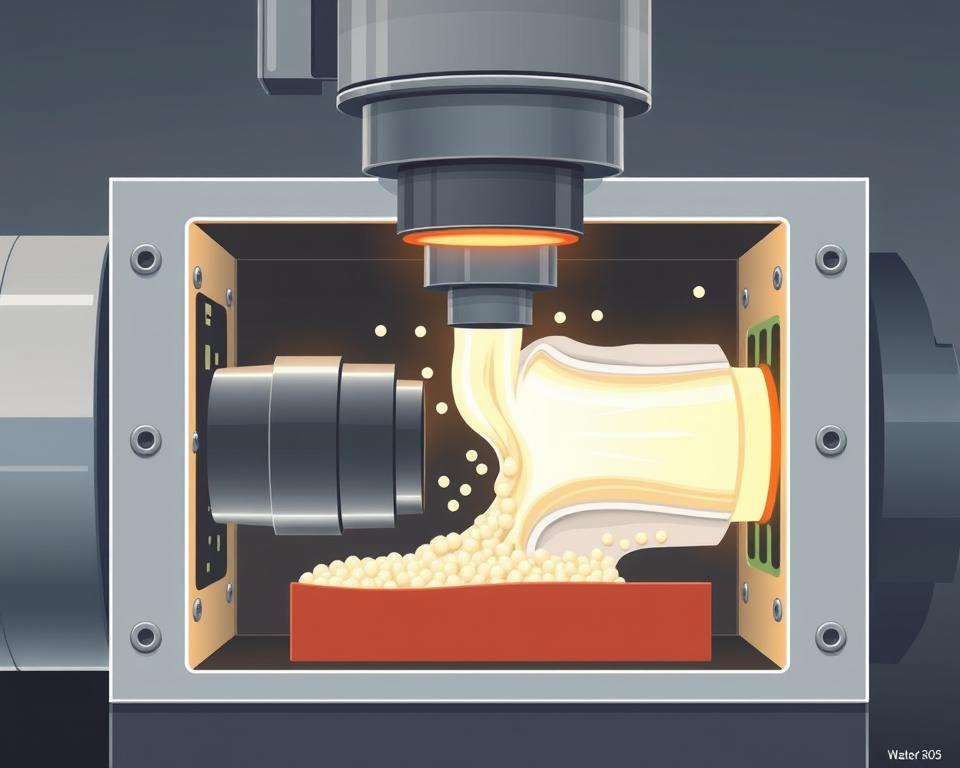

Converting Digital Designs into Molded Parts

Once you’ve chosen your supplier. you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Then comes the real action.

Initially, expect a DFM report. DFM stands for Design for Manufacturability. This is your supplier’s formal feedback on your part design. They’ll flag thick sections prone to sink, sharp edges that stress, or insufficient draft. A thorough DFM is a sign of a professional operation. It’s a collaboration. You iterate with their team to optimize the mold.

With DFM sign-off, toolmaking begins. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These are your initial mold shots. It’s your test of success.

Expect T1s to need tweaks. That’s standard process. Look for small flaws, slight size errors, or surface marks. You supply feedback, they tweak the tool, and T2 plastic mold company samples follow. It could require several iterations. Build buffer time for sample iterations.

Finally, a flawless part arrives. It meets every dimension, the finish is flawless, and it functions exactly as intended. This is now the benchmark sample. You sign off, and it serves as the master quality reference.

Crossing the Finish Line

Landing the golden sample is huge, yet the project continues. Now you’re entering the mass production phase. How can you keep part #10,000 matching your golden sample?

You need a clear Quality Control plan. Often, you hire a pre-shipment inspection service. Again, you can hire a third-party service. They’ll randomly select parts, compare them to specs and golden sample, and deliver a detailed report. They provide a photo-filled inspection report. Only after you approve this report do you authorize the shipment and send the final payment. This simple step prevents you from receiving a container full of scrap metal.

Lastly, plan logistics. Clarify your Incoterms. Are you on FOB terms, where they load and you take over? Or EXW, shifting all transport to you? Your Incoterm selection drives landed expenses.

Overseas sourcing is a marathon. It hinges on strong supplier relations. Treat them like a partner, not just a line item on a spreadsheet. Open dialogue, trust, and rigorous procedure deliver results. Certainly, it’s complex. But with this roadmap, you can succeed, achieve savings, and maintain quality. You’ve got this.